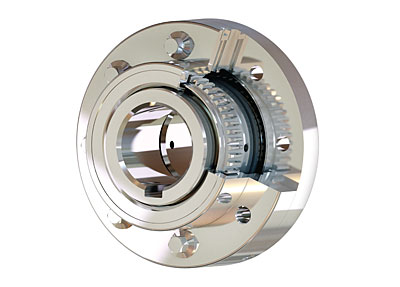

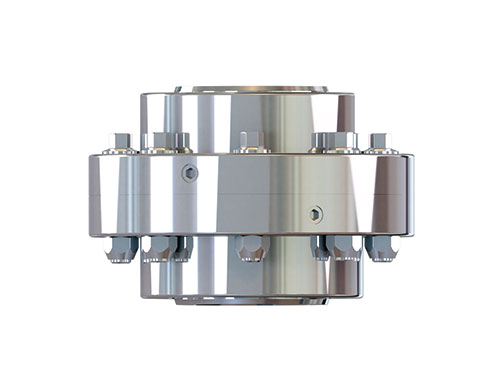

HercuFlex® Labyrinth Seal Flange Style (FXL)

In extreme high contamination environments, Lovejoy has transformed the HercuFlex coupling to integrate an advanced seal design when performance degradation is not tolerable. This advanced gear coupling still encompasses the torque and misalignment capacities that make the HercuFlex coupling an industry leader.

- Unequaled bore and torque capacity

- 1.5° of misalignment per gear mesh

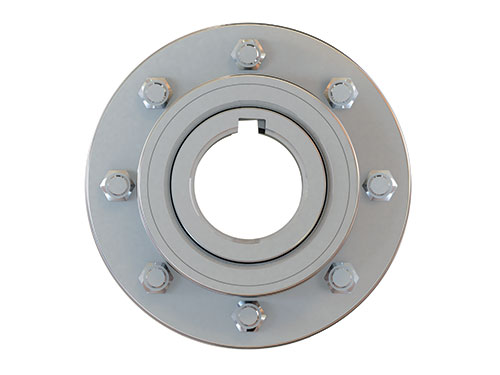

- Improved fastener corrosion resistance

- Advanced seal design intensifying contamination resistance

- Interchangeable with standard AGMA flange interface