By deploying the latest advances in Finite Element Analysis technology, and building off of decades of proven success with the complete

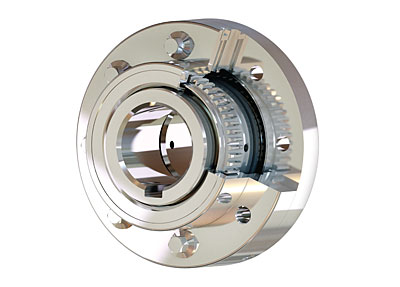

Lovejoy / Sier-Bath gear coupling line, Lovejoy’s engineering team has revolutionized the gear coupling. This revolution, known as HercuFlex

® offers increased nominal torque, larger maximum bore size and longer service life. Despite the advanced nature of these improvements, the HercuFlex Gear Coupling still utilizes the standard AGMA flange interface to ensure field interchangeability.

In addition to unequaled bore and torque capacity while maintaining compliance with standard AGMA flange interfaces, key features include 1.5° of misalignment per gear mesh, stronger alloy steel hubs and sleeves (on the FX, CX, and FXL), improved fastener corrosion resistance, and advanced seal design for increased contamination resistance. Furthermore, the hubs and seals used for both the flange and continuous sleeves HercuFlex gear coupling designs are common and interchangeable parts. This commonality allows for increased inventory rationalization for stocking partners.

By deploying the latest advances in Finite Element Analysis technology, and building off of decades of proven success with the complete

By deploying the latest advances in Finite Element Analysis technology, and building off of decades of proven success with the complete