RunRight® Anti-Vibration Mounts

- Sinusoidal oscillation (RAV D) and impact (RAV) solutions

- Absorbs active and passive vibrations

- Delivers solid-born noise insulation

- Provides shock absorption for impact loads

Resources

RunRight® Anti-Vibration Mounts Product Information

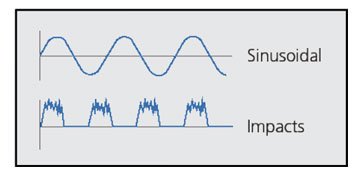

Manufacturers of anti-vibration mounts usually offer machine mounts with varying natural frequencies, to eliminate the excitation frequency of the machine, versus the natural frequency of the anti-vibration mount. Vibration technology differentiates between two types of oscillation signatures. Sinusoidal oscillation of working equipment produces a predictable vibration signature. Sinusoidal oscillations occur on generators, compressors and blowers, which require a soft RAV D mount, whereas, shocks or impacts produce a non-predictable signature. For mixers, crushers, punching presses and shears, a RAV mount would be prefered.

Manufacturers of anti-vibration mounts usually offer machine mounts with varying natural frequencies, to eliminate the excitation frequency of the machine, versus the natural frequency of the anti-vibration mount. Vibration technology differentiates between two types of oscillation signatures. Sinusoidal oscillation of working equipment produces a predictable vibration signature. Sinusoidal oscillations occur on generators, compressors and blowers, which require a soft RAV D mount, whereas, shocks or impacts produce a non-predictable signature. For mixers, crushers, punching presses and shears, a RAV mount would be prefered.

Dampening effect is related to the proportion of the relevant acoustic resistance to acoustic velocity, and the material density. Typically, the ideal amount of isolation of solid-born noise can be expected through the entire frequency range with a rubber-steel mount combination. Isolation in relationship to steel is shown in the chart to the right.

Isolation Properties

Active isolation prevents the direct transfer of a machine’s vibrations into the substructure, frame and building. In order to select anti-vibration mounts, the machine structure stiffness, center of gravity, interfering frequency, and machine location need to be known.

Passive isolation installs a protective barrier between the shocks and vibrations that occur in a factory when sensitive instruments, laboratory equipment, or electronic controls are involved. Sensitive equipment needs to be protected by installing them on soft ant-vibration mounts (RAV D) that will absorb the environmental impacts.