Features

- Maximum misalignment capabilities, with negligible reactionary load, for longer equipment bearing life

- Operates as smoothly when misaligned as when perfectly aligned

- No lubrication and no maintenance required

- Equipment can be visually aligned. No special tools are required, which saves on installation time and cost

- Eliminates premature equipment bearing and seal failure resulting from misalignment forces. This means greater equipment productivity

- Torsionally stiff coupling with no backlash means it is capable of high speed applications, within catalog ratings

- Provides long-term performance and economy

- Available in 5 basic sizes, from 10HP to 900HP

- Standard all-metal and stainless steel versions are both available from stock

- Many configurations are available, including shaft-to-shaft, spacer, floating shaft, and special assemblies

The Deltaflex Difference

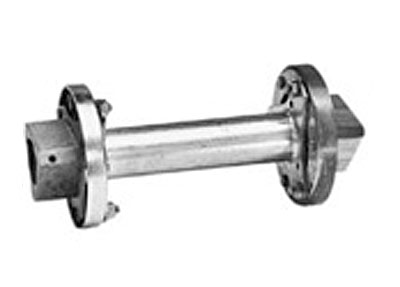

In contrast to most conventional coupling designs, the patented Deltaflex coupling is typically arranged in this manner: a hub, a flex-link at each end of a torque sleeve, and a hub. While most conventional coupling designs use a central flexing element, the Deltaflex uses two, making it a double engaging coupling. The patented concept, along with the method of connecting the hubs to the flexible links, permits the tremendous misalignment capabilities without exerting harmful radial loads.

The Deltaflex coupling consists of four major components: two delta hubs, an inner flange, and an outer flange. The flex-links, as well as the delta mounting plates, are integral to each flange and are factory assembled. The hub is field-assembled to the flange with three axial cap screws. The two flanges are fastened together radially as the two coupling halves are joined to make a complete coupling.

In understanding the design of the Deltaflexit is important to note that the inner and outer flanges, once firmly fastened together with three cap screws, become a rigid “torque sleeve.” The flex links at each end of the torque sleeve accommodate the misalignment generated by the equipment shaft hubs.

Typical Deltaflex Applications

Use Deltaflex couplings to simplify installation and minimize fabrication costs of structural frames. With the large misalignment capability of Deltaflex, extremely close tolerances will be unnecessary.

Typical applications include: compressors, pumps, fans, mixers (vertical and horizontal), turbine

drives, wind tunnels, and single bearing generator drives.

Some other applications include:

Drive-Line – Connecting long shaft lines with Deltaflex takes advantage of angular and parallel misalignment capabilities. Permits ease of installation and reduces radial bearing loads to a minimum.

Indexing Table or Work Positioning Drive – Takes advantage of zero backlash, instant response and constant velocity. Coupling may be between drive motor and gear reduction or on output side of reducer.

Cooling Tower Drive – The Deltaflex floating shaft coupling permits greater ease of installation with its generous axial misalignment capabilities. Also available in stainless steel.